Recent Project News:

FEA Prediction of the Manufacturing Process Induced Residual Stress in a Railroad Wheel is Accomplished!

A current project that demonstrates non-linear thermal and non-linear stress analysis is discussed below. The component analyzed is a railroad wheel, which is rim quenched during the manufacturing process in order to produce a beneficial state of compressive hoop stress in the rim. The beneficial state of hoop stress is accomplished by the autofrettage (self-hooping) process, which was originally applied to artillery pieces such as cannons but is now used in a wide variety of industrial applications.

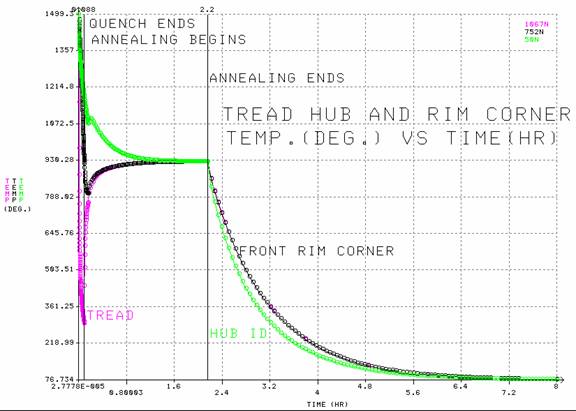

The beneficial state of compressive hoop stress in this application is accomplished by bringing the wheel up to a uniform temperature of 1600oF. Then the tread of the wheel is quenched with room temperature water for several minutes. Next the wheel is put into an 800oF annealing furnace for several hours and finally it is removed and allowed to air cool to ambient conditions.

The customer required the prediction of the state of stress in the wheel when it reached ambient conditions. The first step in the FEA is to solve for the temperatures in the wheel during the eight (8) hour thermal transient. Once the temperatures are produced they are then applied as the thermal load in the non-linear elastic-plastic FEA, which must also include the effects of creep.

The thermal FEA must account for effects of conduction, convection and radiation. The thermal physical properties are all a function of temperature. A typical result from the thermal FEA is shown below, where the temperature of several points on the wheel have been plotted versus time.

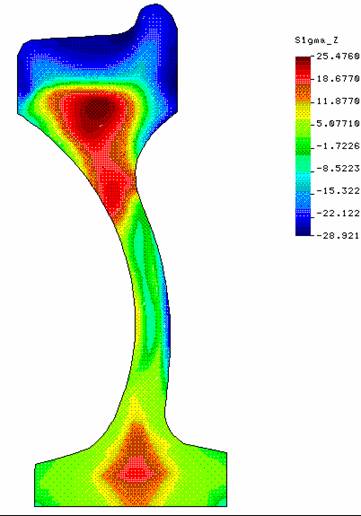

The thermal stress FEA must account for the non-linear stress-strain behavior of the wheel steel and the non-linear effects of creep. All of the mechanical properties are a function of temperature. The elastic-plastic FEA is then conducted for every step in the thermal transient shown above. A typical result from the thermal stress FEA is shown below, where the final ambient residual hoop stress distribution has been plotted.

Experimental measurements of the hoop stress have shown to be in very good agreement with the above FEA predictions. The above FEA was conducted in both ANSYS and COSMOS/M. The results from the two codes were found to be in very good agreement.